Scientists in China have developed a groundbreaking 3D printing method using holographic light fields. The new technique allows tiny, complex components to be printed in just 0.6 seconds, far faster than conventional methods.

The rapid speed could transform manufacturing for industries that rely on small, precise parts. Devices such as mobile phone components and micro-robotics parts may benefit significantly from this technology.

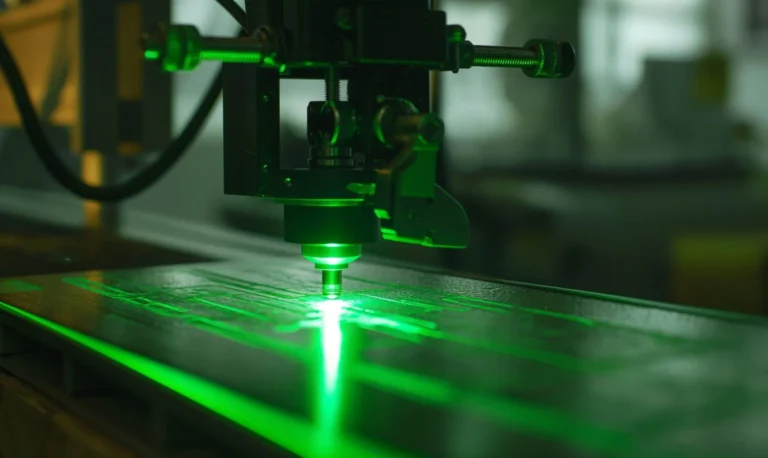

Holographic 3D printing works by projecting a 3D light field onto a material that solidifies instantly in the desired shape. This approach bypasses the layer-by-layer process of traditional 3D printing, enabling much faster fabrication while maintaining high precision.

Researchers say this method not only reduces production time but also allows for intricate designs that were previously difficult or impossible to create. Components with complex internal structures can now be fabricated in under a second.

The breakthrough demonstrates China’s growing leadership in advanced manufacturing technologies. While 3D printing has been widely used worldwide, achieving ultrafast production of microscopic components marks a major step forward for industrial and scientific applications.

Potential applications include electronics, robotics, and medical devices. For example, micro-robots used in medical procedures or tiny sensors in electronics could be manufactured more efficiently and at lower cost.

Experts note that speed alone is not enough; the new method also ensures precision and structural integrity. Early tests indicate that the printed components meet stringent quality standards, suggesting the technology could be ready for commercial use in the near future.

China’s focus on innovation in 3D printing aligns with broader goals in advanced manufacturing and high-tech research. Investment from both government and private sectors has accelerated progress, allowing breakthroughs like this to move from the lab into real-world applications.

The ultrafast printing technique also reduces material waste, as it directly solidifies only the desired structure. This efficiency could help manufacturers meet sustainability goals while increasing output.

Researchers are now exploring how the method can be scaled for larger production runs and more diverse materials. Combining speed, precision, and versatility could make China ultrafast 3D printing a global standard for micro-component manufacturing.

The development signals a new era for high-speed, high-precision manufacturing. By creating tiny, complex parts in fractions of a second, the technology could reshape industries that depend on micro-scale components, from consumer electronics to robotics and medical devices.

China ultrafast 3D printing is expected to attract international attention as companies seek faster, more precise, and sustainable ways to produce miniature components. Analysts predict further breakthroughs as researchers refine the method and expand its industrial applications.